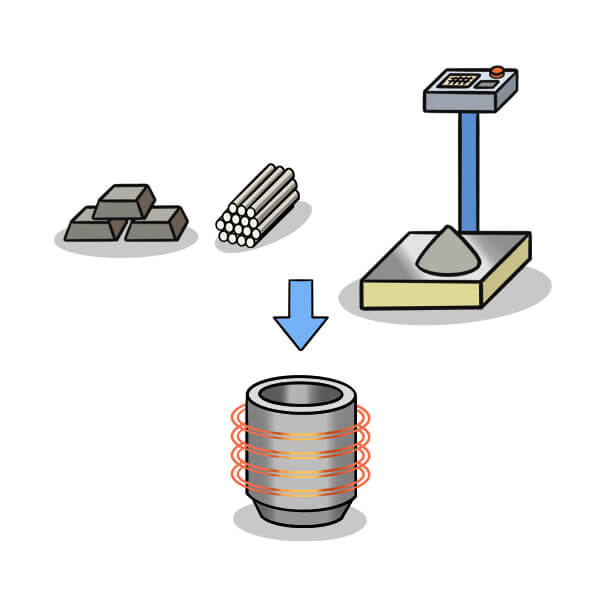

Sintered Neodymium hlau nplaum yog npaj los ntawm raw cov ntaub ntawv raug melted nyob rau hauv lub tshuab nqus tsev los yog inert cua nyob rau hauv ib tug induction melting rauv, ces ua tiav nyob rau hauv lub strip caster thiab txias rau daim ntawv Nd-Fe-B alloy sawb. Alloy strips yog pulverized los ua cov hmoov zoo nrog ob peb microns hauv txoj kab uas hla. Cov hmoov zoo yog tom qab compacted nyob rau hauv ib qho kev taw qhia magnetic teb thiab sintered rau hauv ntom ntom. Tom qab ntawd lub cev yog machined rau cov duab tshwj xeeb, kho nto thiab magnetized.

Qhov hnyav

Qhov hnyav ntawm cov khoom tsim nyog raw khoom yog ncaj qha ntsig txog qhov tseeb ntawm cov hlau nplaum muaj pes tsawg leeg. Purity los yog raw khoom thiab stability ntawm tshuaj muaj pes tsawg leeg yog lub hauv paus ntawm cov khoom zoo. Sintered Neodymium hlau nplaum feem ntau xaiv cov hlau tsis tshua muaj hauv ntiaj teb xws li Praseodymium-Neodymium Pr-Nd mischmetal, Lanthanum-Cerium La-Ce mischmetal, thiab Dysprosium Iron Dy-Fe alloy ua cov khoom siv rau tus nqi vim li cas. Cov ntsiab lus siab melting point Boron, Molybdenum, lossis Niobium ntxiv rau hauv txoj kev ferroalloy. Xeb txheej, suav nrog, oxide, thiab av ntawm cov khoom siv raw yuav tsum tau tshem tawm los ntawm lub tshuab microblasting. Tsis tas li ntawd, cov khoom siv raw yuav tsum nyob rau hauv qhov loj me kom ua tiav cov txiaj ntsig hauv cov txheej txheem melting tom ntej. Neodymium muaj qhov tsis tshua muaj vapor siab thiab cov khoom siv tshuaj lom neeg, tom qab ntawd cov hlau tsis tshua muaj hauv ntiaj teb muaj qee qhov kev poob qis thiab oxidation poob thaum lub sij hawm melting, yog li ntawd, cov txheej txheem hnyav ntawm sintered Neodymium hlau nplaum yuav tsum xav txog ntxiv cov hlau tsis tshua muaj hauv ntiaj teb kom paub meej cov hlau nplaum muaj pes tsawg leeg.

Melting thiab Sawb Casting

Melting thiab sawb casting yog ib qho tseem ceeb rau kev muaj pes tsawg leeg, crystalline xeev, thiab kev faib ntawm theem, yog li cuam tshuam cov txheej txheem tom ntej thiab kev ua haujlwm sib nqus. Cov khoom raw yog rhuab rau molten lub xeev ntawm nruab nrab thiab tsawg zaus induction melting nyob rau hauv lub tshuab nqus tsev los yog inert cua. Casting tuaj yeem ua tiav thaum cov hlau yaj ua tiav homogenization, tso tawm, thiab slagging. Ib tug zoo cam khwb cia ingot microstructure yuav tsum muaj zoo-loj hlob zoo thiab nplua-loj columnar siv lead ua, ces Nd-nplua nuj theem yuav tsum faib raws li grain ciam teb. Tsis tas li ntawd, cam khwb cia ingot microstructure yuav tsum pub dawb ntawm -Fe theem. Re-Fe theem daim duab qhia tau hais tias tsis tshua muaj lub ntiaj teb ternary alloy yog inevitable los tsim -Fe theem thaum qeeb txias. Chav kub muag khoom sib nqus ntawm -Fe theem yuav ua rau kev ua haujlwm sib nqus ntawm cov hlau nplaum, yog li yuav tsum tau inhibited los ntawm kev ua kom txias sai. Txhawm rau kom txaus siab rau qhov xav tau txias txias los tiv thaiv kev tsim tawm ntawm -Fe theem, Showa Denko KK, tsim Strip Casting Technology thiab tsis ntev los no ua cov cuab yeej siv niaj hnub hauv kev lag luam. Uniform faib ntawm Nd-nplua nuj theem thiab cov nyhuv inhibitory ntawm -Fe theem tuaj yeem txo tag nrho cov ntsiab lus ntawm lub ntiaj teb tsis tshua muaj txiaj ntsig zoo rau kev tsim cov hlau nplaum ua haujlwm siab thiab txo tus nqi.

Hydrogen Decrepitation

Hydrogenation tus cwj pwm ntawm tsawg lub ntiaj teb hlau, alloys, los yog intermetallic compounds thiab physicochemical zog ntawm hydride yeej ib txwm yog ib qho teeb meem tseem ceeb nyob rau hauv lub ntiaj teb tsis tshua muaj daim ntawv thov. Nd-Fe-B alloy ingot kuj pom muaj zog hydrogenation nyiam heev. Hydrogen atoms nkag mus rau qhov chaw interstitial ntawm intermetallic compound lub ntsiab theem thiab Nd-nplua nuj grain ciam theem thiab tsim interstitial compound. Tom qab ntawd interatomic nrug nce thiab lattice ntim nthuav dav. Qhov tshwm sim hauv kev ntxhov siab yuav ua rau cov qoob loo tawg (intergranular fracture), crystal fracture (transcrystalline fracture), lossis ductile fracture. Cov decrepitation tuaj nrog crackling thiab yog li hu ua hydrogen decrepitation. Hydrogen decrepitation txheej txheem ntawm sintered Neodymium hlau nplaum kuj hais txog HD txheej txheem. Cov qoob loo ciam teb tawg thiab siv lead ua tawg uas tsim nyob rau hauv cov txheej txheem hydrogen decrepitation ua Nd-Fe-B chav kawm hmoov tsis yooj yim heev thiab muaj txiaj ntsig zoo rau cov txheej txheem dav hlau milling tom ntej. Ntxiv nrog rau kev txhim kho kev ua haujlwm ntawm cov txheej txheem dav hlau milling, cov txheej txheem hydrogen decrepitation kuj yog qhov zoo los kho qhov nruab nrab cov hmoov loj ntawm cov hmoov zoo.

Dav hlau Milling

Dav hlau milling tau ua pov thawj tias yog qhov ua tau zoo tshaj plaws thiab siv tau zoo hauv cov txheej txheem hmoov. Dav hlau milling siv lub dav hlau ceev ceev ntawm cov roj inert kom ceev cov hmoov coarse rau supersonic tshaj tawm thiab cuam tshuam cov hmoov rau ib leeg. Lub hom phiaj tseem ceeb ntawm cov txheej txheem hmoov yog nrhiav qhov tsim nyog qhov nruab nrab particle loj thiab particle loj tis. Qhov sib txawv ntawm cov nta saum toj no qhia txog cov yam ntxwv sib txawv hauv cov nplais macroscopic uas cuam tshuam ncaj qha rau cov hmoov txhaws, kev taw qhia, kev cog lus, demolding thiab microstructure generated nyob rau hauv sintering txheej txheem, ces rhiab heev cuam tshuam magnetic kev ua tau zoo, mechanical zog, thermoelectricity, thiab tshuaj stability ntawm sintered Neodymium hlau nplaum. Qhov zoo tshaj plaws microstructure yog nplua thiab niaj hnub tseem ceeb theem nplej ncig los ntawm du thiab nyias ntxiv theem. Dhau li ntawd, yooj yim magnetization kev taw qhia ntawm lub ntsiab theem grain yuav tsum tau teem raws li kev taw qhia raws li zoo raws li ua tau. Voids, loj nplej, los yog mos magnetic theem yuav ua rau kom txo tau cov intrinsic coercivity. Remanence thiab squareness ntawm demagnetization nkhaus yuav ib txhij txo qis thaum yooj yim magnetization kev taw qhia ntawm grain deviate los ntawm orientation kev taw qhia. Yog li ntawd, cov alloys yuav tsum tau pulverized rau ib leeg-crystal particle li ntawm 3 mus rau 5 microns nyob rau hauv txoj kab uas hla.

Compacting

Magnetic field orientation compacting yog xa mus rau kev siv cov kev sib cuam tshuam ntawm cov hmoov sib nqus thiab cov khoom sib nqus sab nraud kom haum cov hmoov raws li qhov yooj yim magnetization kev taw qhia thiab ua kom nws ua tau raws li qhov kawg magnetization kev taw qhia. Sib nqus teb orientation compacting yog txoj hauv kev tshaj plaws los tsim cov hlau nplaum anisotropic. Nd-Fe-B alloy tau raug crushed rau hauv ib qho siv lead ua ib qho hauv cov txheej txheem dav hlau milling dhau los. Ib leeg siv lead ua particle yog uniaxial anisotropy thiab txhua tus ntawm lawv tsuas yog ib qho yooj yim magnetization kev taw qhia. Sib nqus hmoov yuav hloov mus rau hauv ib leeg los ntawm ntau lub npe nyob rau hauv qhov kev txiav txim ntawm sab nraud magnetic teb tom qab xoob ntim rau hauv pwm, tom qab ntawd kho nws yooj yim magnetization kev taw qhia c-axis kom zoo ib yam nrog sab nraud magnetic teb kev taw qhia ntawm rotating los yog txav. C-axis ntawm alloy hmoov yeej khaws nws cov xwm txheej thaum lub sij hawm compacting txheej txheem. Compacted qhov chaw yuav tsum tau kho demagnetization ua ntej demolding. Qhov tseem ceeb tshaj plaws Performance index ntawm compacting txheej txheem yog orientation degree. Orientation degree ntawm sintered Neodymium hlau nplaum yog txiav txim los ntawm ntau yam, xws li orientation magnetic teb lub zog, particle loj, pom meej ceev, compacting txoj kev, compaction siab, thiab lwm yam.

Sintering

Qhov ceev ntawm qhov compacted tuaj yeem ua tiav ntau dua 95% ntawm txoj kev xav ntom ntom tom qab ua tiav cov txheej txheem sintering nyob rau hauv lub tshuab nqus tsev siab lossis cov cua ntshiab inert. Yog li ntawd, cov voids nyob rau hauv sintered Neodymium hlau nplaum raug kaw uas ua kom muaj kev sib nqus ntawm qhov sib nqus flux ntom thiab tshuaj lom neeg ruaj khov. Txij li cov khoom sib nqus mus tas li ntawm sintered Neodymium hlau nplaum yog ze rau nws tus kheej microstructure, kev kho cua sov tom qab sintering txheej txheem kuj tseem ceeb heev rau kev hloov kho ntawm cov hlau nplaum sib nqus, tshwj xeeb tshaj yog kev coercivity. Nd-nplua nuj grain ciam theem yog ua raws li cov kua theem uas muaj peev xwm los txhawb cov sintering cov tshuaj tiv thaiv thiab rov qab nto defects ntawm lub ntsiab theem grain. Sintering kub ntawm Neodymium hlau nplaum feem ntau yog li ntawm 1050 txog 1180 degrees Celsius. Qhov kub ntau dhau yuav ua rau cov qoob loo loj hlob thiab txo qis kev sib koom tes. Txhawm rau kom tau txais txiaj ntsig zoo tshaj plaws ntawm kev sib koom ua ke, squareness ntawm demagnetization nkhaus, thiab qhov kub thiab txias irreversible poob, sintered Neodymium hlau nplaum feem ntau yuav tsum tau ua ob-theem tempering kub kho ntawm 900 thiab 500 degrees Celsius.

Tshuab dhos

Ntxiv rau cov duab tsis tu ncua nrog qhov loj me me, sintered Neodymium hlau nplaum yog ib qho nyuaj rau kev ua tiav qhov yuav tsum tau ua thiab qhov tseeb qhov tseeb ntawm ib lub sij hawm vim muaj kev txwv hauv cov txheej txheem sib nqus kev sib nqus, yog li, machining yog ib qho kev zam tsis tau rau sintered Neodymium hlau nplaum. . Raws li cov khoom siv cermet, sintered Neodymium hlau nplaum yog qhov nyuaj thiab nkig, ces tsuas yog txiav, drilling, thiab sib tsoo tuaj yeem siv tau rau nws cov txheej txheem machining ntawm cov pa machining tshuab. Cov hniav txiav feem ntau siv pob zeb diamond coated lossis CBN coated hniav. Hlau txiav thiab laser txiav yog zoo suited rau lub machining ntawm tshwj xeeb zoo li tus hlau nplaum, tab sis raug liam ntawm tsawg ntau lawm efficiency thiab siab ua nqi nyob rau hauv lub meanwhile. Drilling txheej txheem ntawm sintered Neodymium hlau nplaum yog feem ntau saws pob zeb diamond thiab laser. Nws yog ib qho tsim nyog los xaiv cov txheej txheem trepanning thaum lub puab qhov ntawm lub nplhaib hlau nplaum loj dua 4 hli. Raws li cov khoom lag luam hauv cov txheej txheem trepanning, trepanned core tuaj yeem siv rau kev tsim lwm cov hlau nplaum me me thiab yog li txhim kho cov khoom siv sib piv. Sib tsoo log rau daim ntawv sib tsoo yog tsim los ntawm kev sib tsoo nto.

Kev kho saum npoo

Kev tiv thaiv saum npoo yog txheej txheem tsim nyog rau cov hlau nplaum Neodymium, tshwj xeeb tshaj yog sintered Neodymium hlau nplaum. Sintered Neodymium hlau nplaum muaj ntau theem microstructure thiab muaj Nd2Fe14B lub ntsiab theem, Nd-nplua nuj theem, thiab B-nplua nuj theem. Nd-nplua nuj theem nthuav tawm muaj zog oxidation nyiam heev thiab yuav tsim cov roj teeb tseem ceeb nrog rau theem tseem ceeb hauv qhov chaw ntub dej. Ib qho me me ntawm cov khoom hloov pauv muaj peev xwm txhim kho cov tshuaj lom neeg ruaj khov ntawm cov hlau nplaum, tab sis tuaj ntawm tus nqi ntawm kev ua haujlwm sib nqus. Yog li ntawd, kev tiv thaiv ntawm sintered Neodymium hlau nplaum feem ntau yog tsom rau ntawm nws qhov chaw. Kev kho deg ntawm sintered Neodymium hlau nplaum tuaj yeem muab faib ua cov txheej txheem ntub thiab qhuav. Cov txheej txheem ntub dej hais txog cov hlau nplaum yog cov txheej txheem kev tiv thaiv saum npoo hauv cov dej ntshiab lossis kev daws teeb meem. Cov txheej txheem ntub dej muaj xws li phosphate, electroplating, electrolessplating, electrophoresis, txau txheej, thiab dip txheej. Cov txheej txheem qhuav hais txog cov hlau nplaum yog cov txheej txheem kev tiv thaiv saum npoo los ntawm kev siv lub cev lossis tshuaj lom neeg yam tsis muaj kev sib cuag nrog kev daws teeb meem. Cov txheej txheem qhuav feem ntau muaj lub cev vapor deposition (PVD) thiab tshuaj vapor deposition (CVD).

Magnetization

Feem ntau ntawm cov hlau nplaum ruaj khov yog magnetized ua ntej ua haujlwm rau lawv cov ntawv thov. Cov txheej txheem Magnetization yog hais txog kev siv lub teb sib nqus raws li kev taw qhia ntawm cov hlau nplaum ruaj khov thiab ua tiav cov txheej txheem saturation nrog lub zog sab nraud sib nqus. Txhua yam khoom siv hlau nplaum tas mus li xav tau qhov sib nqus sib nqus lub zog kom ua tiav kev saturation hauv kev taw qhia magnetization. Remanence thiab intrinsic coercivity yuav tsawg dua li nws qhov tseem ceeb tshwj tsis yog tias sab nraud magnetic teb lub zog qis dua kev saturation magnetic teb. Cov hlau nplaum tas mus li tuaj yeem muab faib ua hom isotropic thiab anisotropic yam raws li seb puas muaj qhov yooj yim magnetization kev taw qhia lossis tsis. Raws li cov hlau nplaum anisotropic nrog siab intrinsic coercivity, sintered Neodymium hlau nplaum yuav tsum tau magnetized ntawm impulse magnetization. Lub capacitor yuav raug them tom qab rectification, ces lub zog hluav taws xob nyob rau hauv capacitor instantaneous tawm mus rau lub magnetizing fixture. Magnetizing fixture tuaj yeem tsim cov hlau nplaum sib nqus thaum lub sijhawm tam sim no muaj zog tam sim no los ntawm nws. Yog li ntawd, cov hlau nplaum ruaj khov nyob rau hauv coil yuav magnetized. Muaj ntau yam qauv magnetization tuaj yeem ua tiav ntawm sintered Neodymium hlau nplaum kom ntev li ntev tau tsis cuam tshuam nrog nws txoj kev taw qhia.