Lub practicability ntawm cov hlau nplaum mus tas li yuav txiav txim los ntawm stability ntawm remanenceBr, intrinsic coercivityHcj, thiab cov khoom siv hluav taws xob siab tshaj plaws(BH) maxnyob rau hauv sab nraud mob. Magnet nrog siab duaBrtuaj yeem muab qhov muaj zog magnetic teb zog, ces siab duaHcjtuaj yeem ua haujlwm zoo dua los tiv thaiv kev cuam tshuam. Tus nqi ntawm(BH) maxsawv cev rau cov hlau nplaum ruaj khov lub peev xwm los muab lub zog magnetostatic. Nws tuaj yeem pom los ntawm daim duab hauv qab no, siab(BH) maxCov hlau nplaum tuaj yeem muab tib lub zog sib nqus nrog kev siv tsawg dua, tom qab ntawd kev txhim kho keeb kwm ntawm cov hlau nplaum ruaj khov yog qhov tseem ceeb ntawm kev ua haujlwm siab dua.

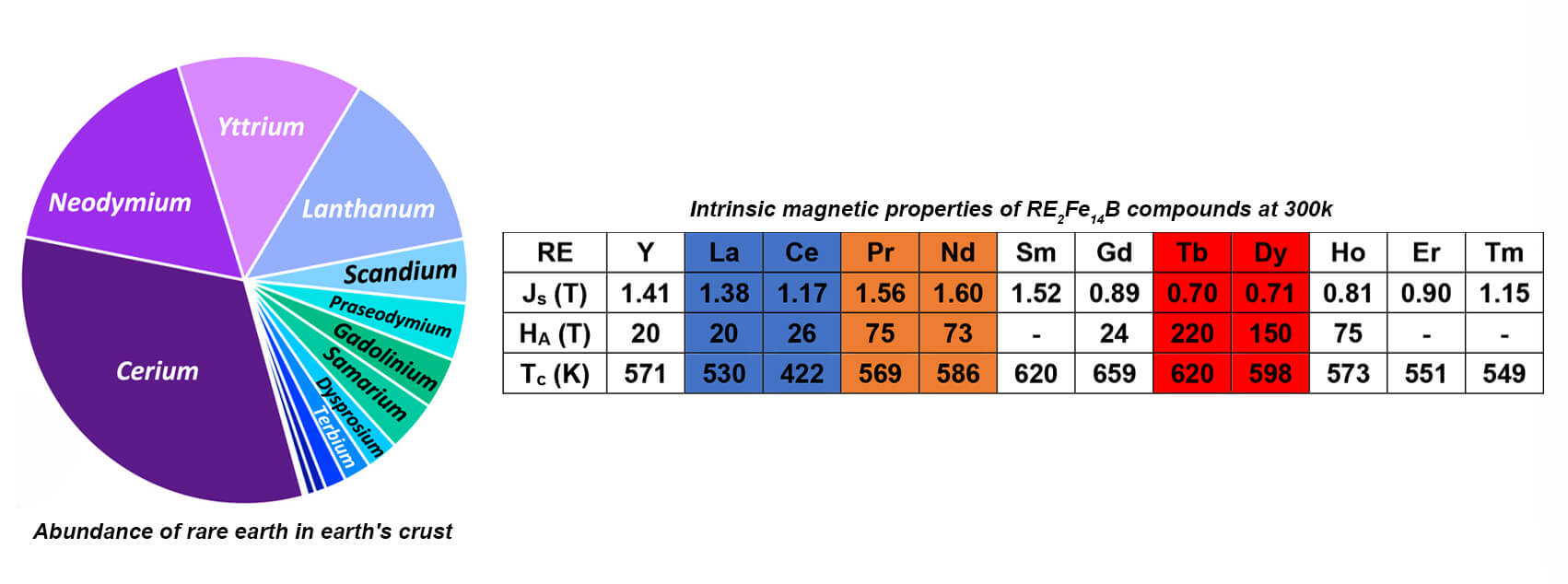

Feem ntau ntawm cov ntsiab lus tsis tshua muaj hauv ntiaj teb tuaj yeem tsim RE2Fe14B compound nrog Fe thiab B, thiab Nd2Fe14B compound muaj qhov siab tshaj plaws saturation magnetization thiab ua haujlwm magnetocrystalline anisotropy teb ntawm cov RE2Fe14B cov ntsiab lus. Tsis tas li ntawd, cia ntim ntawm Neodymium nyob rau hauv lub ntiaj teb lub crust yog ntau ntau uas muaj peev xwm tswj tau cov saw hlau ruaj khov thiab tus nqi kom zoo dua.

Ntau qhov kev soj ntsuam microstructure qhia tias muaj rau theem muaj nyob rau hauv cov hlau nplaum Neodymium sintered, ces Nd2Fe14B theem tseem ceeb thiab Nd-nplua nuj theem yog qhov paub zoo tshaj plaws vim lawv cov teebmeem ntawm kev ua haujlwm sib nqus. Nd2Fe14B theem tseem ceeb yog tib theem sib nqus nyuaj hauv cov hlau nplaum sintered thiab nws qhov ntim feem txiav txim siabBrthiab(BH) maxNd-Fe-B alloy. Nd-nplua nuj theem plays lub luag haujlwm tseem ceeb hauv kev sib nqus hardening ntawm sintered Neodymium hlau nplaum. Nws muaj pes tsawg leeg, qauv, kev faib tawm, thiab morphology yog rhiab heev rau cov txheej txheem txheej txheem. Nd-nplua nuj theem yog qhov zoo dua nyob rau hauv daim ntawv ntawm cov txheej txheem txheej thiab txuas ntxiv faib rau hauv cov qoob loo ciam teb.

Coercivity Enhancement ntawm Sintered Neodymium Magnets

Lub tshuab hluav taws xob cua tshuab hluav taws xob, lub zog tshiab tsheb, cov khoom siv hluav taws xob txuag hluav taws xob hauv tsev, thiab lub davhlau ya nyob twg ntse xov tooj tshiab yog txhua yam xav tau sintered Neodymium hlau nplaum tsis tsuas yog muaj siab.(BH) max, tab sis kuj muaj superiorHcj. Nws ib txwm yog qhov teeb meem loj los txhim khoHcjthaum tseem tuav tau siabBrthiab(BH) max.

Lub hauv paus coercivity ntawm sintered Neodymium hlau nplaum feem ntau cuam tshuam los ntawm microstructure thiab muaj pes tsawg leeg. Optimization ntawm microstructure tsom rau cov nplej refinement thiab txhim kho kev faib ntawm Nd-nplua nuj theem. Kev sib xyaw tuaj yeem ua kom zoo dua los ntawm kev ntxiv lwm cov ntsiab lus los txhim kho magnetocrystalline anisotropy teb ntawm lub ntsiab theem nplej. Muaj kev sib raug zoo ntawm coercivity ntawm sintered Neodymium hlau nplaum thiab magnetocrystalline anisotropy teb ntawm lub ntsiab theem grain. Qhov ntawd yog hais tias, qhov siab dua qhov magnetocrystalline anisotropy teb ntawm lub ntsiab theem nplej, qhov siab dua qhov coercivity ntawm sintered Neodymium hlau nplaum. Tus HAntawm Dy2Fe14B and Tb2Fe14B yog suav tias siab dua Nd2Fe14B, tom qab ntawd ntxiv me me ntawm Dy lossis Tb keeb los hloov Nd atom hauv theem tseem ceeb lattice yuav tsim (Nd, Dy)2Fe14B or (Nd, Tb)2Fe14B nrog siab HAuas tuaj yeem txhim kho qhov kev sib koom tes zoo. Cov txheej txheem nquag siv ntxiv suav nrog cov txheej txheem kev sib xyaw ua ke, cov txheej txheem kev hloov pauv ntawm cov ciam teb, thiab cov txheej txheem lis ciam diffusion.

Txheej txheem Alloying

Alloying txheej txheem yog xa mus rau ntxiv ib feem ntawm HREE Dy los yog Tb rau raw khoom ntawm sintered Neodymium hlau nplaum, ces tag nrho cov ntsiab lus qhia homogenization ntawm muaj pes tsawg leeg los ntawm cov txheej txheem melting. Coercivity mechanism ntawm sintered Neodymium hlau nplaum qhia tau hais tias reversed magnetic domain nyiam nucleate nyob rau hauv ciam teb cheeb tsam ntawm lub ntsiab theem, thiab uniform faib ntawm HREE yuav ua rau cov khoom pov tseg thiab raug nqi. Qhov tseem ceeb tshaj, antiferromagnetic coupling ntawm Fe atoms thiab Dy atoms yuav ua rau muaj zog sib nqus dilution nyhuv thiab ntau deteriorate.Brthiab(BH) max.

Cov Txheej Txheem Kev Hloov Kho Kev Ciam Teb

Txhawm rau txhim kho qhov kev siv piv ntawm HREE thiab tsis txhob sib nqus dilution nyhuv, cov txheej txheem hloov pauv hloov pauv tau thov. Ua ntej, grain ciam hloov txheej txheem tsim Nd2Fe14B lub ntsiab alloy thiab HREE-nplua nuj auxiliary alloy feem, ces nias thiab sintering tom qab sib tov ob alloys raws li qhov feem pua. Dy thiab Tb yuav diffuse mus rau theem tseem ceeb ntawm cov nplej ciam teb thaum lub sij hawm sintering, yog li daim ntawv (Nd, Dy)2Fe14B or (Nd, Tb)2Fe14B magnetic hardening khaubncaws sab nraud povtseg ntawm ciam teb cheeb tsam ntawm lub ntsiab theem thiab li no txo nucleation ntawm reversed magnetic domain. Txawm tias cov txheej txheem kev hloov pauv ntawm cov ciam teb tau txhawb nqa qhov kev siv piv lossis HREE, HREE tseem yog qhov tseem ceeb nyob rau sab hauv ntawm cov theem tseem ceeb ntawm cov nplej thiab ua rau muaj kev sib nqus dilution. Cov txheej txheem hloov pauv ib thaj tsam ntawm cov nplej muaj qhov tseem ceeb rau cov txheej txheem tom ntej ntawm cov kab lis kev cai.

Grain Boundary Diffusion Txheej txheem

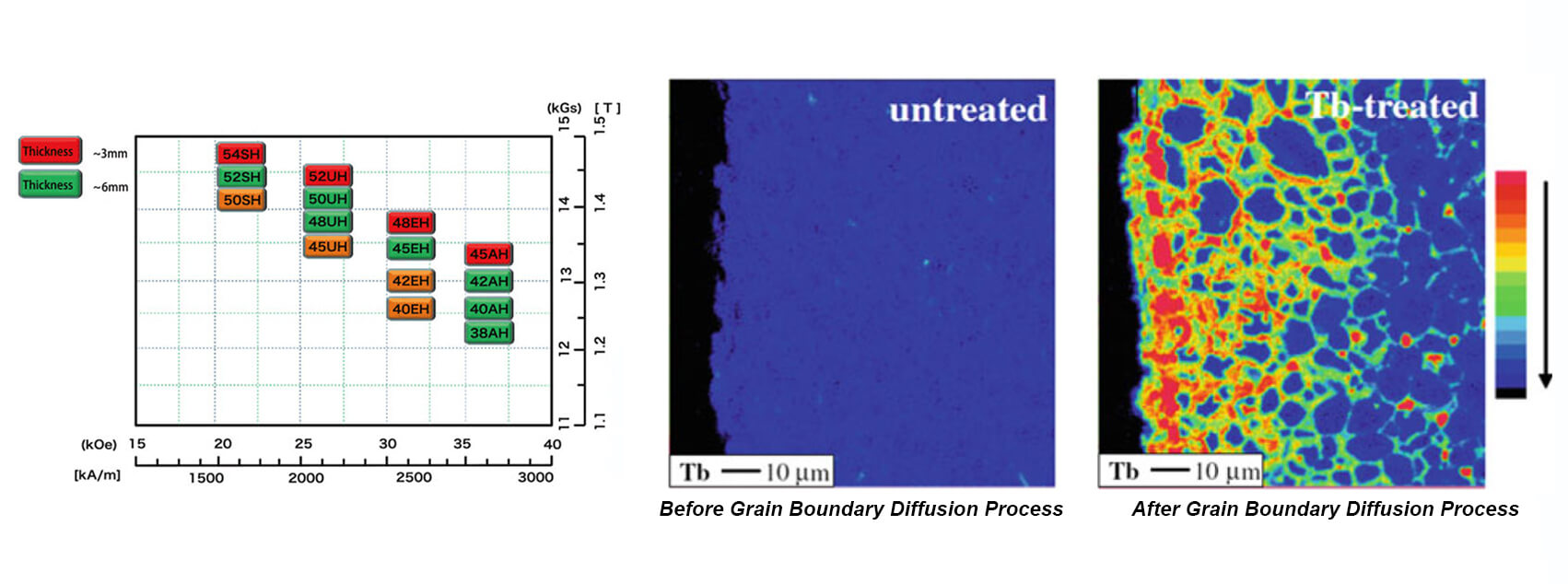

Cov txheej txheem ua qoob loo ciam teb yog pib los ntawm kev qhia HREE txheej rau cov hlau nplaum saum npoo, tom qab ntawd ntsib kev kho cua sov ntawm lub tshuab nqus tsev saum toj kawg nkaus ntawm lub melting point ntawm Nd-nplua nuj theem. Yog li ntawd, HREE lub caij diffuse mus rau hauv cov hlau nplaum raws li cov qoob loo ciam teb thiab daim ntawv (Nd, Dy, Tb)2Fe14B core-plhaub qauv nyob ib ncig ntawm grain ntawm lub ntsiab theem. Tom qab ntawd anisotropy teb ntawm lub ntsiab theem yuav raug kho kom zoo, nyob rau hauv lub caij no, grain ciam theem ua ntau nruam thiab ncaj uas yuav tsis muaj zog sib nqus sib nqus coupling ntawm lub ntsiab theem. Qhov tseem ceeb tshaj plaws ntawm cov nplej ciam diffusion txheej txheem yog cia cov hlau nplaum nceHcjthaum tib lub sij hawm tswj siabBr. Tsis zoo li cov txheej txheem alloying, HREE cov ntsiab lus tsis tas yuav nkag mus rau theem tseem ceeb, yog li tsim kom muaj qhov txo qis ntawm HREE thiab tus nqi nqi hauv cov pa high-coercivity sintered Neodymium hlau nplaum. Cov ciam teb nplej tseem muaj peev xwm tsim tau qee cov qib tshiab uas yav dhau los tsis tuaj yeem xav txog ntawm cov txheej txheem alloying, xws li N54SH thiab N52UH.

Grain ciam diffusion kev kho mob yuav raug siv tom qab lub machining txheej txheem. HREE txheej tuaj yeem tau txais los ntawm kev txau, lub cev vapor deposition (PVD), electrophoresis, thiab thermal evaporation.

Cov kev txwv ntawm Cov Txheej Txheem Nroj Tsuag Nroj Tsuag Diffusion

Grain ciam diffusion txheej txheem yog tsuas yog txwv los ntawm lub thickness ntawm cov hlau nplaum, thiab kev nce qib ntawm intrinsic coercivity txo qis thaum lub thickness nce. Nce diffusion kub los yog lub sij hawm ntev diffusion tuaj yeem txhawb qhov tob thiab siab ntawm diffused HREE, tom qab ntawd txhawb qhov ntim feem ntawm HREE core-plhaub qauv. Txawm li cas los xij, qhov kub thiab lub sijhawm ntau dhau yuav ua rau cov qoob loo loj hlob ntawm cov theem tseem ceeb, nyob rau lub sijhawm no, cov qauv theem thiab kev faib tawm ntawm Nd-nplua nuj theem kuj tseem yuav hloov.